How to Choose the Right LED Power Supply Factory for Your Lighting Projects

When it comes to designing and executing lighting projects—whether it’s a commercial space, residential building, industrial plant, or even smart city infrastructure—there’s one component that often gets less attention than it deserves: the power supply.

You can have the most sophisticated LED fixtures in the world, but if your power supply can’t keep up—fails, flickers, or simply doesn’t match your voltage and load needs—your entire lighting setup could fall apart. That’s why choosing the right LED Power Supply factory is one of the most critical decisions you’ll make.

To put it simply, a LED Power Supply factory is not just a supplier—it’s the heartbeat behind your lighting reliability and performance. In this article, we’ll walk through what to look for in a factory, how to evaluate them, and why your choice today will directly impact your long-term project success.

What Does a LED Power Supply Factory Really Do?

Before diving into how to choose one, let’s first define what we mean when we say “LED Power Supply factory.” Unlike a distributor, a factory is where the power supplies are actually manufactured—designed, assembled, tested, and packaged.

This means everything from the quality of raw materials to the sophistication of their engineering team plays a role in the final product you receive. A great LED Power Supply factory doesn’t just follow specs; they innovate, maintain strict quality control, and often develop custom solutions for unique lighting challenges.

Why the Right Factory Matters

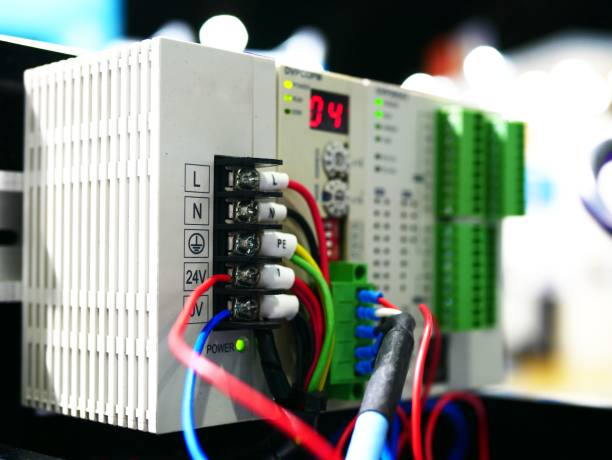

So why all the fuss? Because power supplies are the silent engine behind every LED installation. They convert AC to DC, regulate current, protect against surges, and ensure your LEDs run at the right temperature and voltage.

If the factory cuts corners, your LEDs may burn out prematurely, flicker, or fail entirely. Worse, a low-quality power supply can pose safety risks like short circuits or overheating. That’s not a risk worth taking.

Working with the right LED Power Supply factory ensures you get high-efficiency drivers that are durable, compliant with safety standards, and built to perform under real-world conditions.

Key Factors to Consider When Choosing a LED Power Supply Factory

Let’s break down what you should actually be looking for when vetting factories.

1. Manufacturing Certifications and Standards

One of the first things to check is whether the factory has the right certifications. Look for:

ISO 9001 (quality management)

ISO 14001 (environmental responsibility)

UL, CE, RoHS, and FCC certifications on their products

These aren’t just fancy stamps—they prove the factory follows international manufacturing standards and produces safe, reliable products.

2. Experience and Track Record

It’s easy for a factory to say they make great power supplies, but the proof is in the projects.

How long have they been in business?

Have they worked with international clients?

Do they have testimonials or case studies?

A seasoned LED Power Supply factory will have a portfolio of successful installations in different environments—from humid outdoor signage to high-end interior retail stores.

3. Customization Capabilities

Lighting projects aren’t one-size-fits-all. You might need a specific dimming interface, IP67 waterproof casing, or low-profile housing. A good factory should be able to customize drivers based on your technical requirements.

If their answer to every question is “only standard products,” that’s a red flag. A true partner is flexible and innovative.

4. In-House R&D Team

A factory with its own research and development (R&D) department is a strong signal of quality. Why? Because it means they’re not just assembling parts—they’re engineering improvements, testing new components, and staying ahead of industry trends.

Ask if they’re developing energy-efficient designs, smart-dimming solutions, or power supplies compatible with IoT systems. These innovations can future-proof your project.

5. Product Range and Specialization

Some factories specialize in LED strip lighting power supplies, while others excel in high-wattage industrial drivers. You’ll want a factory that has experience with your type of project.

Check for:

Constant voltage vs. constant current drivers

Wattage range

Indoor vs. outdoor applications

Dimming technologies (0-10V, DALI, TRIAC, PWM)

Matching their strengths to your project needs ensures a better outcome.

6. After-Sales Support and Warranty

Even the best-made products occasionally face issues. That’s why a strong after-sales service is essential.

Do they offer a warranty? (Most reputable factories offer 3-5 years.)

Can they assist with replacements or technical questions?

How fast is their response time?

The relationship shouldn’t end after the purchase. A factory that stands behind its product is one you can trust.

7. Global Shipping and Logistics

If you’re sourcing from overseas, check whether the factory can handle international logistics efficiently.

A well-established LED Power Supply factory will have experience shipping to different countries, understand import/export requirements, and offer reliable lead times.

Late shipments can delay your entire project—so logistics matter.

FAQs: Choosing a LED Power Supply Factory

Q1: Can I visit the LED Power Supply factory before placing a large order?

A: Absolutely! In fact, many reputable factories welcome factory tours, especially for bulk buyers. If you can’t travel, ask for a video walkthrough or virtual tour.

Q2: How important is location when choosing a factory?

A: While location can affect shipping times and import duties, what matters more is the factory’s track record, quality, and ability to communicate clearly and deliver on time.

Q3: Are all LED power supplies from China low quality?

A: Not at all. China is home to many world-class LED Power Supply factories. The key is to vet the manufacturer carefully, just as you would anywhere else in the world.

Q4: How do I compare two different factories?

A: Start by comparing certifications, warranty periods, customization options, communication responsiveness, and customer reviews or references. It’s also a good idea to order samples.

Q5: What’s the typical lead time for production?

A: It depends on your order size and customization. For standard products, 2–4 weeks is common. Custom solutions might take 6–8 weeks.

Conclusion: Power Your Project with the Right Partner

In the LED world, the power supply may sit behind the scenes, but it plays a starring role in performance, safety, and longevity. Choosing the right LED Power Supply factory is more than a procurement decision—it’s a partnership for your project’s success.From ensuring product quality and safety to offering tailored solutions and dependable support, a good factory acts as a true extension of your team. Don’t settle for shortcuts or the cheapest quote. Look for factories that align with your goals, understand your industry, and are as invested in your outcomes as you are.So, whether you’re lighting up an office tower, outfitting a smart home, or installing an outdoor LED display, remember: your power is only as strong as the factory behind it.