CNC Swiss Machining Services: Revolutionizing Precision Manufacturing

CNC Swiss machining services have become an integral part of modern manufacturing, providing industries with the ability to produce high-precision components that meet tight tolerances and complex geometries. This advanced machining process is particularly beneficial for producing small parts with intricate designs, making it essential for sectors like aerospace, automotive, medical devices, and electronics. The efficiency, accuracy, and versatility of CNC Swiss machining make it a preferred choice for manufacturers who need to produce small, high-quality parts in large quantities or for prototypes.

What is CNC Swiss Machining?

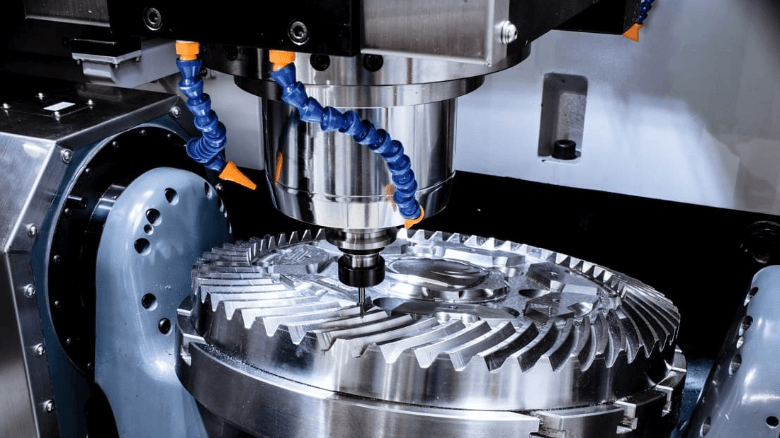

CNC Swiss machining refers to a process that uses a computer-controlled lathe, known as a CNC Swiss machine, to produce precise parts by feeding the material into the machine while a rotating tool cuts or mills it. This technique is distinguished by its use of a guide bushing that supports the workpiece as it rotates, allowing for highly accurate cuts. The term “Swiss” comes from the fact that this type of machining originated in Switzerland, where the technique was developed to make precision components.

The key advantage of CNC Swiss machining is its ability to machine parts that require high precision and tight tolerances. The machine is capable of performing a wide range of operations, including turning, drilling, tapping, and milling, all within a single setup. This minimizes handling, reduces errors, and improves efficiency.

See also: The Importance of Technology Assessments and Strategies for Business Success

Key Benefits of CNC Swiss Machining Services

1. High Precision and Tight Tolerances

One of the main reasons manufacturers choose cnc swiss machining services is the remarkable precision the process offers. Swiss machines are capable of achieving tolerances as tight as 0.0001 inches, which is crucial for applications that demand the highest level of accuracy. The guide bushing mechanism helps minimize vibrations and errors during the cutting process, ensuring that parts are produced with exceptional accuracy. This level of precision is especially important in industries like aerospace, medical devices, and electronics, where even the smallest deviation can cause significant issues.

2. Capability to Machine Complex Geometries

CNC Swiss machining services are ideal for producing parts with complex geometries. The multi-axis movement of the machine allows for the simultaneous cutting of several features, such as undercuts, grooves, and contours, without requiring additional setups or operations. This capability enables the creation of intricate components with high detail and precision, which would be difficult to achieve with traditional machining methods.

By using Swiss machines, manufacturers can create parts with features that are both inside and outside the workpiece, ensuring that intricate and precise designs are met with ease. This reduces the need for multiple machining steps and makes the entire process more efficient and cost-effective.

3. Increased Efficiency and Reduced Lead Times

CNC Swiss machining services improve efficiency by integrating multiple machining processes into a single setup. This eliminates the need for transferring parts between different machines, reducing handling time and the risk of errors. By completing several operations at once, the process is not only faster but also more efficient.

Additionally, Swiss CNC machines are capable of machining materials at a faster rate, reducing production times and lead times. This is particularly beneficial for businesses that need to produce parts quickly or meet tight deadlines. The combination of speed and precision makes CNC Swiss machining services a valuable resource for high-volume production runs, prototypes, or custom orders.

4. Superior Surface Finish

Another key benefit of CNC Swiss machining services is the high-quality surface finish it provides. Swiss machines use fine cutting tools, which result in smooth, polished surfaces that are ideal for parts that require coatings or plating. The smooth surface finish is particularly important for applications in the medical, aerospace, and automotive industries, where components must meet strict quality standards for performance and durability.

For example, in the medical field, components like implants and surgical tools need to have smooth, biocompatible surfaces to ensure they do not cause irritation or damage when in contact with human tissue. The precision and surface finish capabilities of CNC Swiss machining help meet these stringent requirements.

5. Versatility in Material Options

CNC Swiss machining services are not limited to specific materials, making it a versatile option for manufacturers. Swiss machines can handle a wide range of materials, including metals such as stainless steel, titanium, aluminum, and brass, as well as plastics and composite materials. This allows manufacturers to choose the best material for each application based on factors such as strength, corrosion resistance, weight, and heat tolerance.

In industries like aerospace, where parts must withstand high temperatures and stresses, CNC Swiss machining can produce components from heat-resistant alloys. In the medical device industry, where biocompatibility is crucial, the ability to work with titanium and other biocompatible materials makes Swiss machining an ideal choice.

Industries That Benefit from CNC Swiss Machining Services

Aerospace

The aerospace industry relies heavily on precision manufacturing to ensure that parts can withstand the extreme conditions in which they operate. CNC Swiss machining services are particularly beneficial for producing complex aerospace components such as turbine blades, connectors, fasteners, and valves. These parts often require high strength, durability, and resistance to heat and corrosion, making the precision offered by Swiss machining a perfect fit for this industry.

Conclusion

CNC Swiss machining services provide manufacturers with a high-precision, efficient, and versatile solution for producing intricate, small parts with tight tolerances. The ability to handle complex geometries, achieve superior surface finishes, and work with a wide range of materials makes Swiss machining an ideal choice for industries such as aerospace, medical devices, automotive, and electronics.

With its combination of speed, accuracy, and versatility, CNC Swiss machining has revolutionized precision manufacturing. By reducing lead times, improving efficiency, and delivering high-quality parts, Swiss machining continues to be a cornerstone of modern manufacturing, meeting the growing demands of industries that rely on small, intricate components. As technology advances and industries continue to evolve, CNC Swiss machining services will remain a critical tool for producing parts that meet the highest standards of quality and performance.